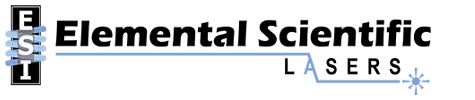

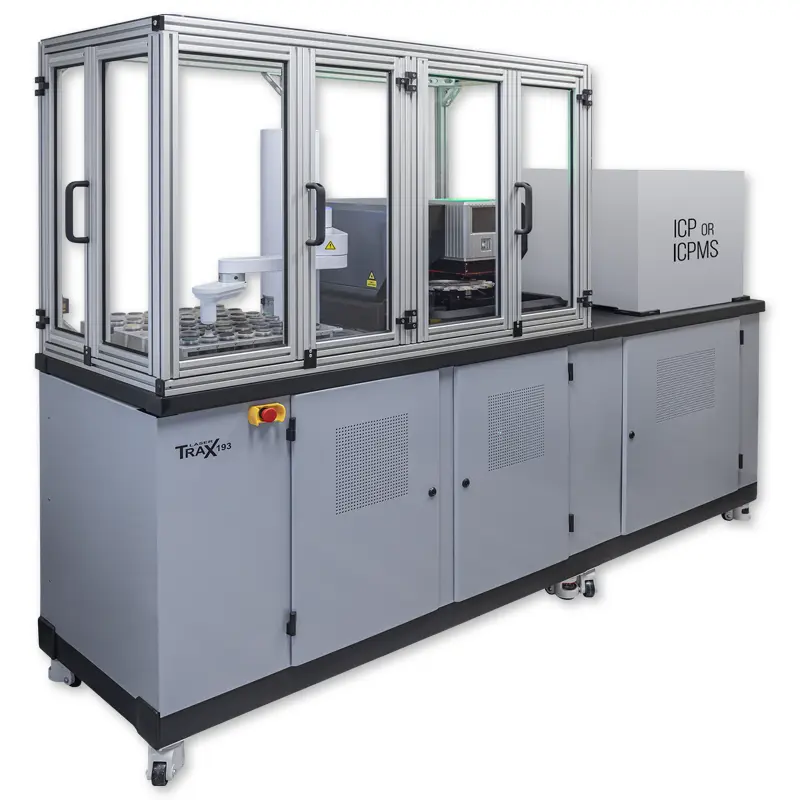

The first fully automated laser ablation system

LaserTRAX is the world’s first fully automated high throughput laser ablation-analytical system. Ideal for mining, exploration, metallurgy and manufacturing environments where bulk and trace elemental results are needed in high volume. LaserTRAX eliminates acid digestion for safer and greener operation, is adaptable to a variety of sample configurations (e.g. XRF fusion beads or pressed pellets), and reduces cost per sample for fast return on investment.

Improvements throughout the elemental analysis workflow

APPLICATIONS:

- Mining exploration and geochemistry

- Battery manufacture and testing

- Soils and sediments

- Foodchain safety

- Ore screening

- Materials quality control

- Waste product screening kylecordova

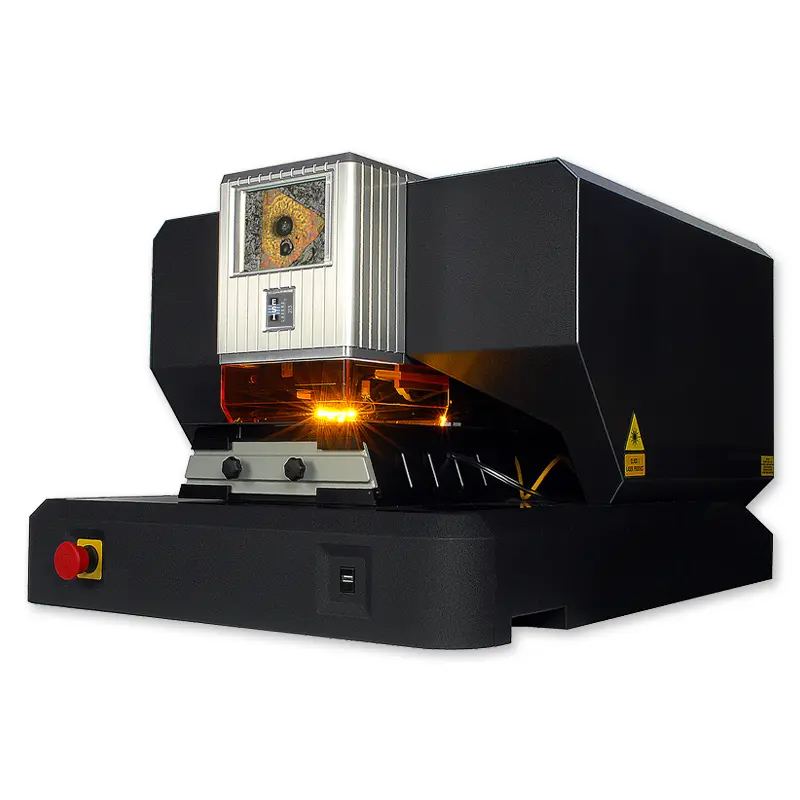

SAMPLE TYPES:

- Fusion beads

- Pressed powders

- Glass

- Metals and Alloys

- Plastics

- Food/plant materials

- Papers/filters

- Slag

ECONOMICAL:

- Save 40-80% costs per sample

- Return on investment in 6-12 months

- Maximizes lab efficiency

- Low cost of ownership

- Savings in time, reagents, energy and human resources

DATA QUALITY:

- Lower detection limits

- Accurate, precise and reproducible

- Simplifies methods to improve outcomes

- Data traceability from sample to result

- Accessible cloud-based data

WORKFLOW IMPACT:

- A single LaserTrax analysis can replace up to 4 solution-digestion methods

- Eliminate acid exposure for a safer lab environment

- Greener workflow reduces waste

- Modernizes work environment and reduces operator error

- Maximizes lab capacity

- Serve clients better through fast data access